Boonrawd Brewery Company Limited, Thailand’s leading beverage company, continues to advance and elevate its smart manufacturing processes toward a Smart Factory model, focusing on three core pillars: advanced technology, efficient production processes, and workforce capability development. These efforts are designed to ensure production standards that are consistently "best-in-class" to uphold consumer trust and align with sustainability guidelines for the organization, the community, and the environment. In this regard, the company has signed an agreement with REPCO NEX Company Limited (REPCO NEX), a subsidiary of SCG Chemicals (SCGC) renowned for its expertise in comprehensive industrial technology and solutions. The collaboration involves the implementation of the DRS by REPCO NEX (Digital Reliability Solutions by REPCO NEX) smart digital solution to optimize production efficiency, enhance machinery reliability, minimize losses, and elevate manufacturing standards, while delivering tangible progress toward corporate and environmental sustainability goals.

Mr. Piti Bhirombhakdi, First Senior Executive Vice President and Chief Production Officer of Boonrawd Brewery Co., Ltd., said, “The core of the Boonrawd Brewery Group lies in producing high-quality products that meet consumer needs. For more than 92 years, the company has continuously developed and elevated its production processes. This includes adopting new technologies to enhance production efficiency, reduce redundancy and unnecessary processes, and applying digital technologies to advance production toward smart manufacturing. At the same time, we focus on upskilling our workforce to foster flexibility, enabling them to adapt to rapid change, work effectively alongside advanced manufacturing technologies, and achieve sustainable growth.”

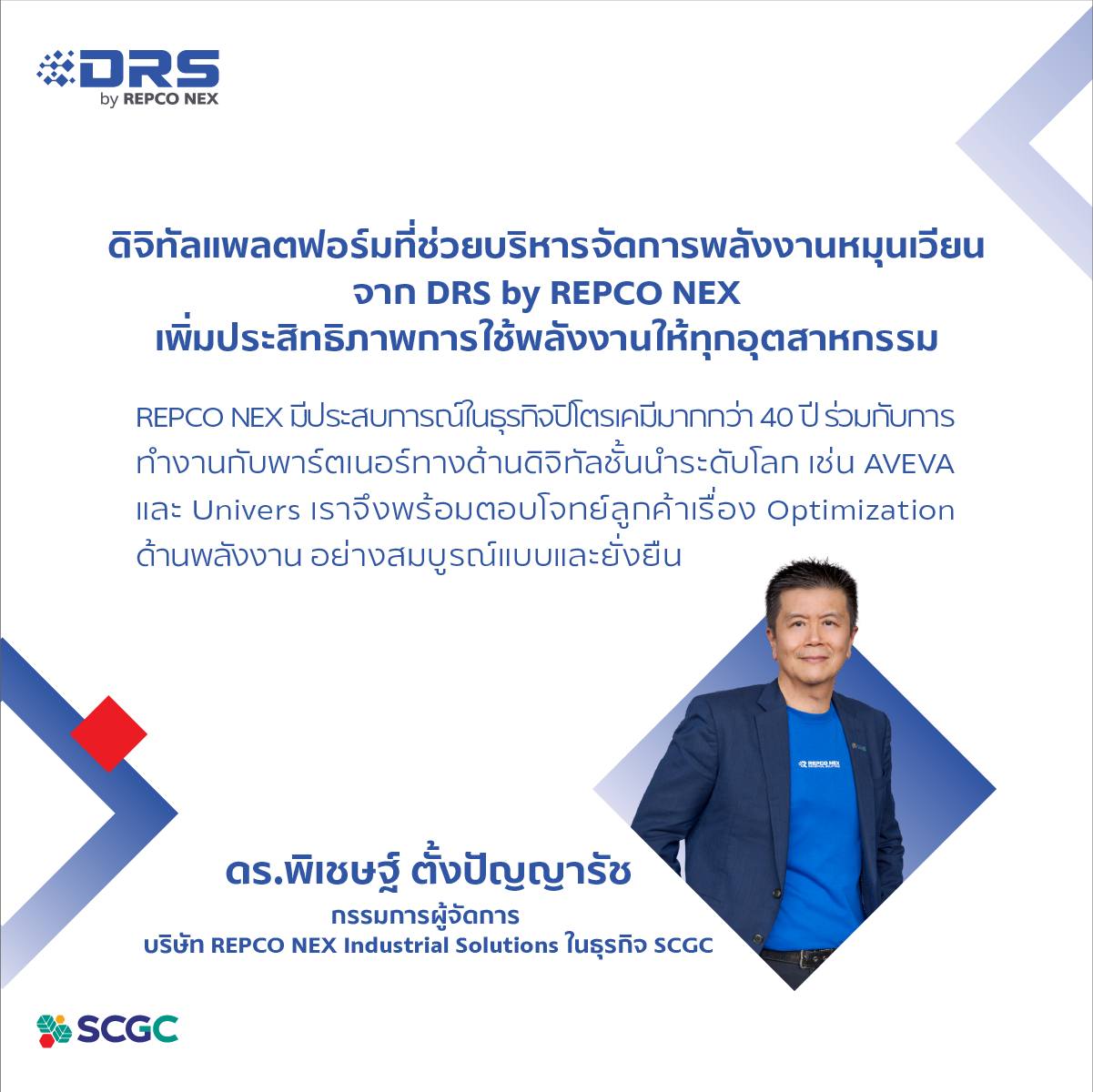

Dr. Pichet Tangpanyarat, Managing Director of REPCO NEX Company Limited (REPCO NEX), a subsidiary of SCGC, said, "This collaboration with Boonrawd Brewery Group integrates SCGC’s expertise in digital technology and engineering through the application of the smart digital solution, DRS by REPCO NEX, with Boonrawd Group’s hands-on experience in food and beverage manufacturing processes to elevate its factories toward a smart manufacturing. This initiative will tangibly and sustainably enhance competitive capabilities while simultaneously promoting environmental sustainability and serving as a key driving force for Thailand’s industrial sector moving forward.”

The DRS by REPCO NEX smart digital solution represents a synergistic integration of human capital and digital technology. It has been developed to address industrial requirements with measurable results and precision. It facilitates the comprehensive enhancement of manufacturing efficiency, including continuous machinery operation, production optimization, and the reduction of losses resulting from non-conforming processes.

The solution comprises:

1) Smart Maintenance, a fully integrated, digitally driven maintenance system;

2) Digital Transformation to support manufacturing operations and production resource management; and

3) a Renewable Energy Management Platform capable of forecasting energy output in advance, detecting and alerting operators to equipment abnormalities, and providing actionable recommendations. Furthermore, the platform enables renewable energy generation at maximum efficiency.