WIRELESS MACHINE CONDITION MONITORING SYSTEM

BENEFITS

- Highest accuracy of measurement with wireless technology.

- Early detection for abnormality.

- Reduce inspection and maintenance costs.

- Safe work conditions from vibration measurement.

FEATURES

- Edge AI for automated diagnostic covering:

- Unbalance

- Misalignment

- Looseness

- Bearing defect

- Gear defect

- 24/7 machine condition monitoring via REPCO NEX web application.

- User-friendly visualized dashboard.

- Customizable alarm notification and automatic notification.

- Flexible networking mode.

- Wide area coverage.

- Low power consumption.

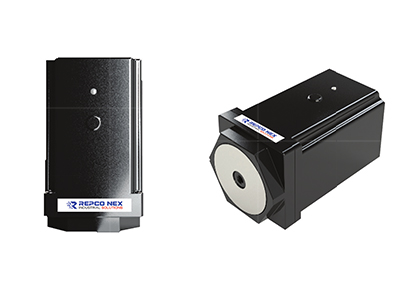

WIRELESS VIBRATION SENSOR SPECIFICATIONS

|

Analysis Parameter |

3-axis Vibration and Surface Temperature |

|

Frequency range |

X-Axis Range: 1 Hz - 10 kHz |

|

Frequency resolution |

0.8 Hz |

|

Vibration measure range |

Velocity (RMS) : 0.2 to 350 mm/s |

|

Temperature Measurement range |

-30 - 85°c |

|

Explosion Proof Specification |

Ex ia IIC T4 Ga |

|

International Protection Standard (IP) |

IP67 |

|

Installation |

Magnetic adsorption/thread M5 |

|

Size |

50x50x85 mm without magnetic base |

|

Weight |

250g (battery included) |

|

Battery capacity |

9,600mAh (replaceable) |

|

Battery lifetime |

2 years (Overall vibration every hour & |

WIRELESS PROTOCOL SPECIFICATIONS

|

Protocol |

LPWAN |

|

RF bands |

920 – 925 MHz |