CiBot™ provides robotic solutions for furnace and boilers, assisting in identifying carburization, bulging and bowing of radiant coils. The data gathered by CiBot™ can be used to interpret any abnormalities in heat distribution along the coils, and accurately determine remaining life of tubes. Several CiBot™s can be operated simultaneously to shorten the inspection time.

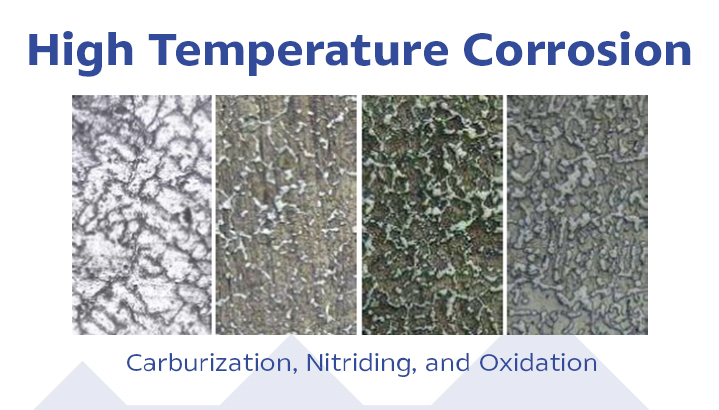

Why CiBot™? Carburization

The phenomenon that carbon from hydrocarbon feedstock inside the radiant tube diffuses into the material matrix is called carburization. Carbon, then, binds with chromium in the material matrix and forms primary and secondary carbides at the grain boundaries. These carbides decrease material ductility, toughness, strength, etc. Moreover, when the chromium content is depleted due to carburization, some materials especially high nickel- and chromium-content alloys such as 35Ni-25Cr and 45Ni-35Cr alloys may change their phase from non-ferromagnetic to ferromagnetic. This magnetic-related change due to carburization can be detected by using specifically designed sensors.

Benefit of CiBot™

- CiBot™ provides a great number of data points to assist in plant operation and maintenance operations. Can effectively perform coil condition and remaining life assessment

- CiBot™ precisely identifies weak spots before failure and without human error

- No scaffold works and work-at-height

- CiBot™ offers quick reliable and precise inspection

Carburization Inspection Robot: CiBot-CR

The carburization inspection robot has been developed to measure and collect carburization data from the radiant tube while the furnace is shutdown. The robot is intentionally designed not only to replace the use of handheld carburization detector in order to decrease man-hours used inside the confined working space for scaffolding work and carburization inspection, but also to enhance the inspection accuracy and repeatability.

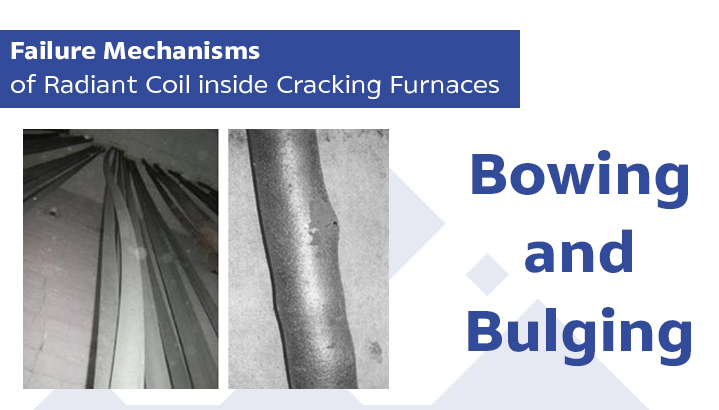

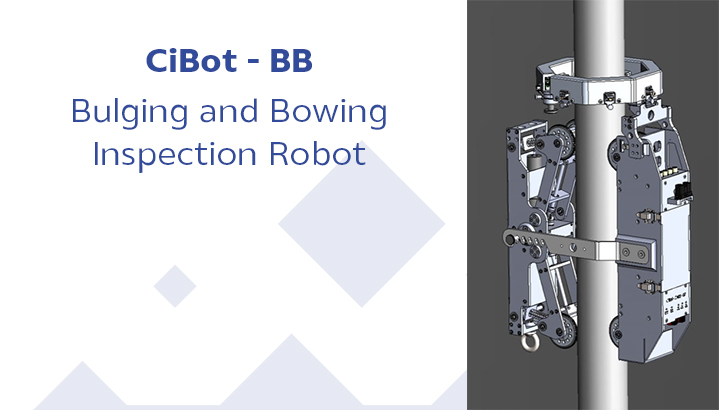

Bulging and Bowing Inspection Robot :

CiBot-BB

The bulging and bowing inspection can also be carried out using robot. The necessity of bowing and bulging inspection is recommended as per API RP 573.

The bulging sensors indicate the diameters of tube at different orientation along the length of tubes while the robot is climbing the tube. The measurement enables detection of tube deformation, which can be interpreted as bulging condition. The maximum diameters at specific elevations are reported.

The bowing inspection applies position of robot while climbing along the tube to represent the shape of tube. The misalignment of tube centerline and the locus of robot indicate the curving of tube. The distance of this misalignment is reported.