Corrotex™ IoT by REPCO NEX provides Corrosion Under Insulation (CUI) detections with high accuracy. Corrotex™ requires no power source and is easy to install. The data collected from Corrotex™ is visualized online for easy access and monitoring, Higher performance when paired with REPCO NEX - CUI Management Program.

INNOVATIVE CUI SENSOR

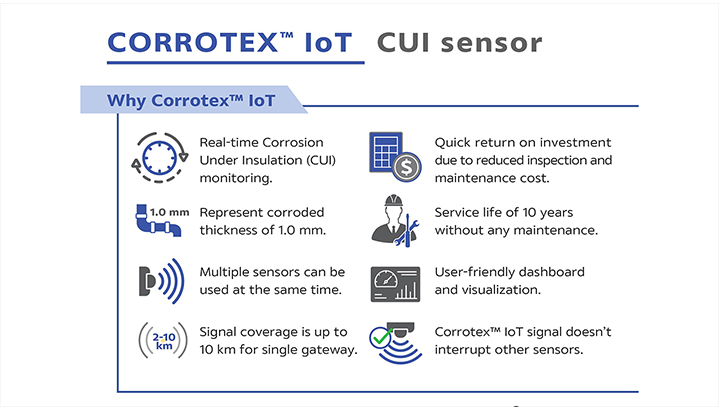

- Real-time monitoring corrosion under insulation (CUI) by the unique device.

- Early assess CUI damage without insulation removal.

- Prevent CUI unpredicted cases.

- Reduce inspection and maintenance costs.

- Quick return on investment.

FIELD DEVICE

- Applicable for carbon and low alloy steel.

- Represent corrosion at pipe and equipment surface.

- Detect corroded thickness of 1.0 mm.

- Duct and water protection (IP65 minimum).

- 10+ years lifetime.

- Explosion protection certified.

MONITORING SYSTEM

- Real-time update

- Web application.

- User-friendly.

- Available on PC, laptops, mobile phones, and smart devices.

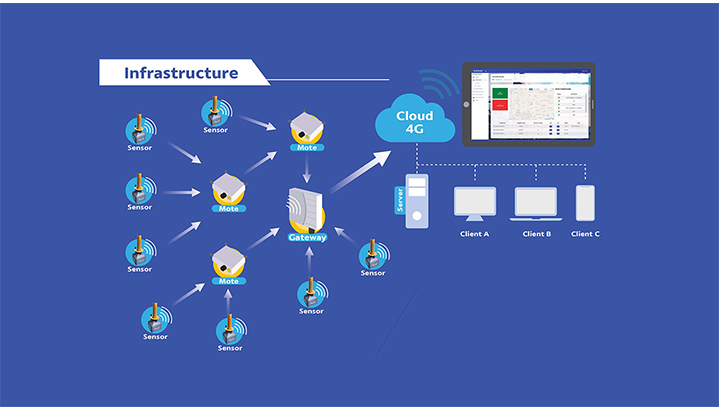

INFRASTRUCTURE - LPWAN

- Signal coverage is up to 10 km for a single gateway.

- Multiple gateways or repeaters can be applied for extending the monitoring area with no limitation.

- Loe power consumption.

- Signal system does not interrupt other sensors.

BENEFITS

Increase Plant Reliability

- Prevent CUI leak by early CUI detection.

- Enhance plant visibility by focusing on CUI.

- Real-time notification.

Cost Saving

- Cost savings more than the conventional.

- Save inspection cost.

- Reduce unnecessary inspection costs e.g. insulation, scaffolding, and manpower.

SPECIFICATIONS

|

Suitable CUI application |

Warm, non-cyclic |

|

Applicable metal |

Carbon steel, low alloy steel |

|

Representing corroded thickness when trigger |

< 1.0 mm |

|

Operating temperature |

25 - 200°C |

|

Maximum temperature |

230°C |

|

Maximum insulation thickness |

80 mm |

|

Required area for installtion |

50 mm |

|

Required drill hole for installation |

24 mm |

|

Signal coverage distance |

2 km - 10 km |

|

Signal type |

LPWAN |

|

Battery service life |

10 years |

|

Explosion proof |

IEC Ex Ia IIC T4 Ga IP65 |