Transforming Today’s Factories

Modern manufacturing faces increasing pressure to maximize output, reduce losses, and respond quickly to market changes. Yet, many factories still rely on delayed reports and manual monitoring that limit their ability to detect and act on issues in real time. The result is avoidable downtime, higher costs, and missed opportunities for efficiency gains.

The Smart Manufacturing Solution

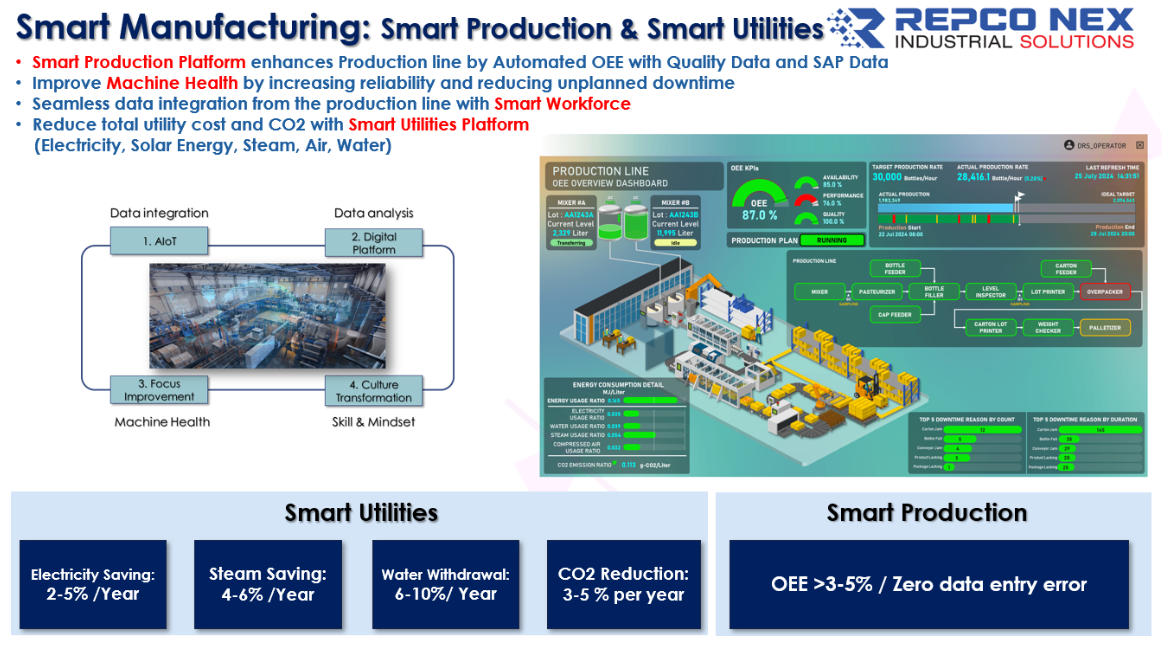

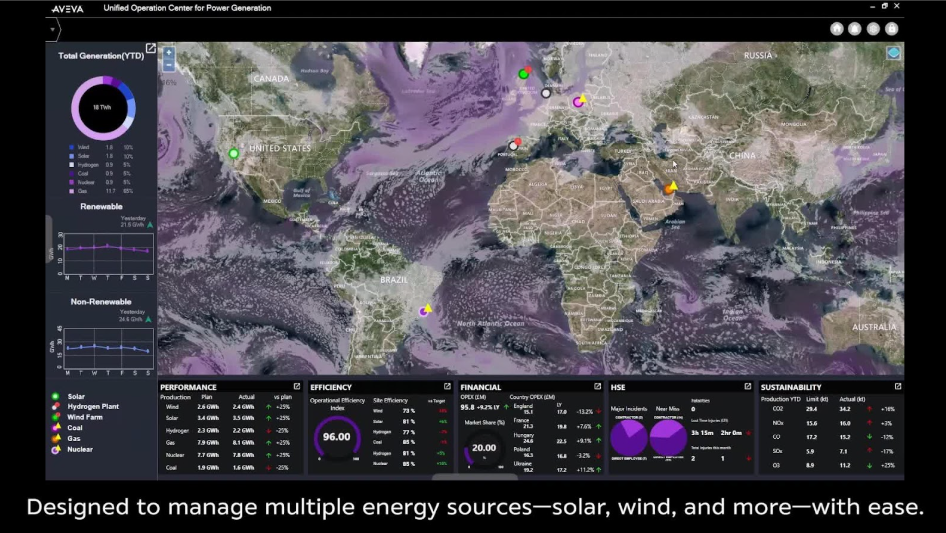

REPCO NEX introduces the Smart Manufacturing Solution — an integrated approach that brings together smart sensors, AI-powered analytics, and digital platforms to empower operators and decision-makers alike.

Key elements include:

- Factory Health Intelligence – Real-time visibility into equipment status and performance.

- AI-Driven Decision Making – Predictive and prescriptive analytics to recommend the best course of action.

- Smart Workforce Enablement – Tools and culture transformation to help teams respond faster and more effectively.

- Scalable Systems – Designed to start small (single production line) and expand to cover full-scale factories.

Proven Impact on Performance

In practice, this solution has already delivered tangible results. A leading beverage manufacturer improved Overall Equipment Effectiveness (OEE) by more than 5% through faster detection and response. Operators received real-time alerts, enabling them to act quickly with confidence. And thanks to a flexible, scalable design, the solution was ready to expand from one line to an entire plant.

Beyond Technology: A Culture of Performance

Smart Manufacturing is not just about deploying digital tools — it’s about building a data-driven culture where people, processes, and technology work together. By empowering the workforce with timely insights and actionable intelligence, factories can reduce avoidable losses, strengthen accountability, and sustain continuous improvement.