The Challenge of Boiler Operations

Boilers are among the most critical assets in a power plant — yet they are also among the most vulnerable. Tube leaks caused by erosion, overheating, or corrosion can strike suddenly, forcing plants into unplanned shutdowns. Traditional inspection methods only cover accessible areas and often leave blind spots, making it difficult to detect risks early enough to act.

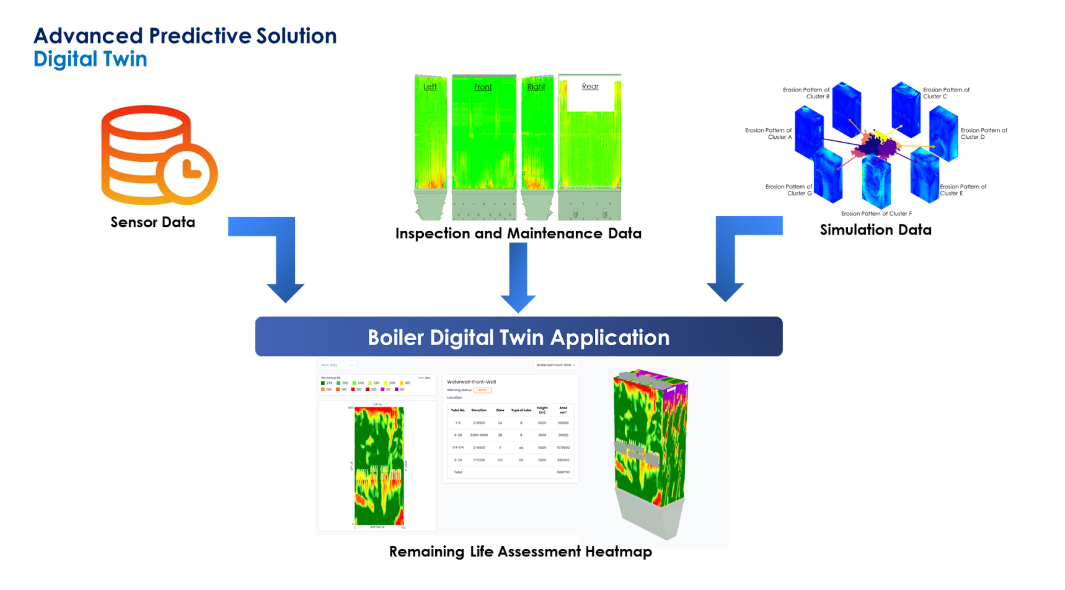

A Digital Replica for Smarter Operations

The Boiler Digital Twin Solution from REPCO NEX is designed to change this. By creating a high-accuracy digital replica of real-world boilers, power plants can simulate operations under different conditions, from varying fuel types to fluctuating load demands. Coupled with AI-powered analytics, the solution forecasts boiler tube lifespan and provides actionable insights for proactive maintenance planning.

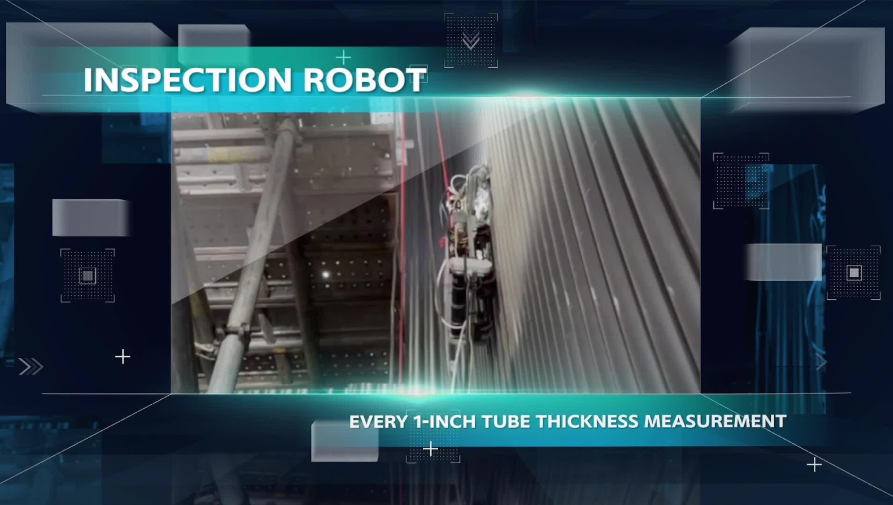

To complement the simulation, the Boiler Inspection Robot performs comprehensive thickness mapping of every tube — far beyond the reach of manual inspection. This combination ensures that hidden risks are uncovered and managed before they escalate.

Key Benefits at a Glance

- Sustainable Operations – Improves efficiency and extends equipment lifespan, supporting a greener factory.

- Predictive Maintenance – Forecasts tube degradation based on operating scenarios, reducing downtime.

- Unplanned Shutdown Prevention – Prevents sudden leaks and failures through accurate predictions and inspections.

- Energy Optimization – Enhances fuel usage and operational efficiency to lower costs and emissions.

- Enhanced Safety – Reduces risks of manual inspection in hazardous environments.

Proven in the Field

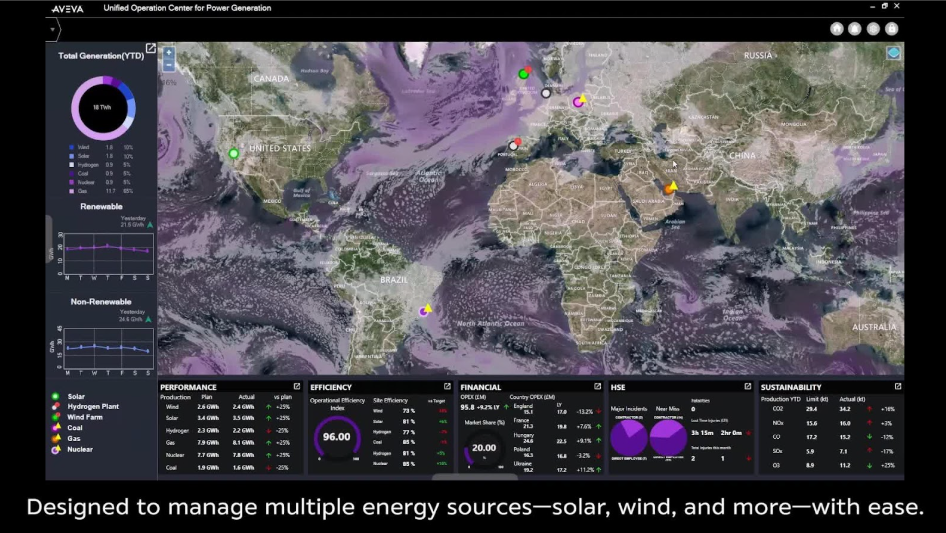

The Boiler Digital Twin has already been implemented with success at Power Plants, where it has enabled smarter decision-making and more reliable operations. By combining digital simulation, robotics, and predictive analytics, plants can achieve higher availability, safer workplaces, and more sustainable outcomes.