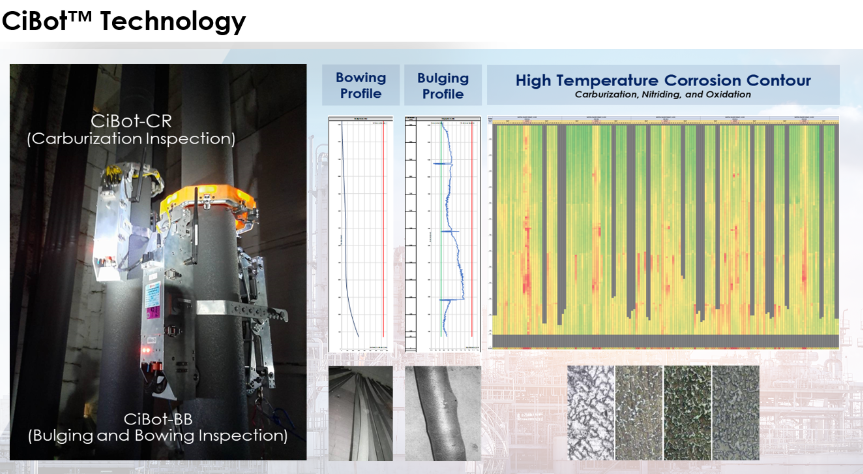

The Challenge of Furnace Tube Inspections

Ethylene cracking furnaces are at the heart of petrochemical production, but their performance depends heavily on the condition of furnace tubes. Traditional inspection methods — relying on portable sensors and manual measurements — collect only limited data and often provide inaccurate evaluations. These blind spots can lead to undetected damage, costly breakdowns, and unplanned shutdowns.

A Smarter Way to Inspect

To address these challenges, REPCO NEX introduces the Coil Inspection Robot (CiBot) — an advanced robotic solution that carefully inspects furnace tubes every centimeter, ensuring accuracy, reliability, and safety. By autonomously navigating through the complex environment of ethylene furnaces, CiBot delivers real-time data and actionable insights that enable operators to plan proactive maintenance and optimize furnace performance.

Key Benefits

- Increased Safety – Reduces manual inspections in hazardous environments, safeguarding workers.

- Cost Savings – Detects abnormalities early, preventing costly downtime and repairs.

- Energy Efficiency – Improves heat distribution and furnace performance, lowering energy consumption.

- Environmental Responsibility – By optimizing efficiency, helps reduce carbon emissions.

- Enhanced Maintenance Strategies – Provides comprehensive insights for proactive planning and extended equipment life.

Proven Across Global Leaders

CiBot has already gained worldwide recognition and adoption. Featured in Hydrocarbon Processing Magazine and introduced at the 2019 Inspection and Mechanical Integrity Summit, CiBot has established itself as a trusted technology for improving furnace reliability, efficiency, and sustainability.