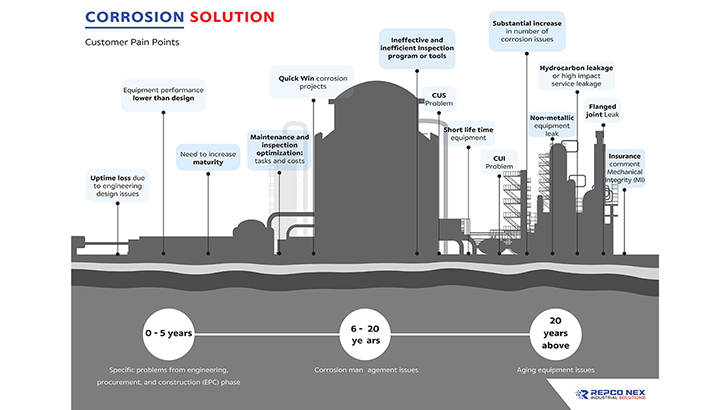

REPCO NEX Corrosion Solution provides end-to-end service for managing static equipment. We combine our technical proficiency and field experience of over 40 years in maintenance and engineering to help our customers improve reliability and extend the service life of critical assets. Providing maintenance solutions such as Mechanical Integrity assessment with Fitness-for-Service (FFS Level 3) by using Finite Element Analysis (FEA) and Computational Fluid Dynamics simulation (CFD), pipe lift up technology for Corrosion Under Support (CUS) problem, Corrosion Under Insulation (CUI) monitoring system and management, and digital IoT sensors in our Digital Reliability Platform for asset care.

WHY REPCO NEX CORROSION SOLUTION?

- More than 40 years of intense experience in dealing with various corrosion problems throughout the whole plant life span, especially in petrochemical plants.

- More than 1,000 success cases in preventing, controlling, and solving corrosion problems.

- Innovative patented corrosion control devices for corrosion under insulation (CUI), corrosion under support (CUS), etc.

- Highest level of corrosion and material selection specialist certified by NACE

- High-competent workforces certified by NACE, APL, ASNT, etc.

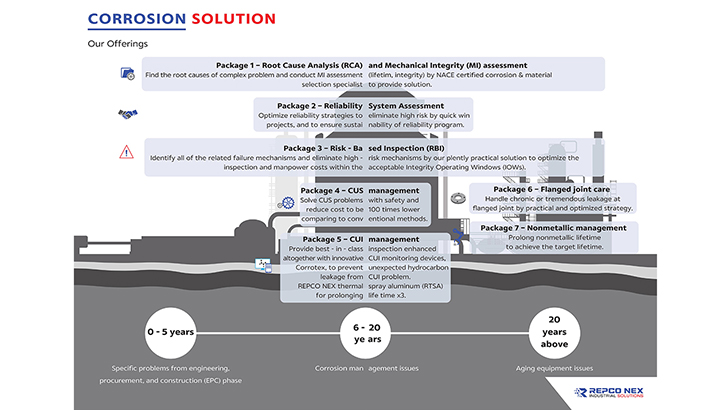

OUR CORROSION SOLUTION PACKAGES

PACKAGE 1 ROOT CAUSE ANALYSIS & MI ASSESSMENT

REPCO NEX offers a root cause analysis (RCA) service to find all key and/or combinations of root causes that lead to equipment failure. The service also includes mechanical integrity (MI) assessment to affirm equipment integrity and remaining life prior to the continuing operation.

"Practical Solution to Eliminate and Mitigate Corrosion Provided"

Root Cause Analysis:

- On-site visit investigation by a corrosion expert.

- Operating history and inspection data analysis.

- Failure analysis comparing with REPCO NEX failure library.

- Root cause analysis led by NACE-certified corrosion specialist.

- Suggestions for problem-solving using REPCO NEX best practices.

MI Assessment:

- Fitness - for - service and remaining life assessment Level 1 and 2 complying with API 579.

- Fitness - for service and remaining life assessment Level 3 using Finite Element Analysis (FEA) plus Computational Fluid Dynamics (CFD).

- Practical recommendation from our rich experience provided.

PACKAGE 2 RELIABILITY SYSTEM ASSESSMENT

Perform benchmarking gap analysis to find and eliminate all remaining high-risk and high-impact reliability issues in order to increase uptime and reduce the number of equipment breakdowns.

Set up quick-win projects that have a high return on investment (ROI).

Optimize reliability strategies and build a reliability roadmap to sustain the reliability program in order to achieve zero hydrocarbon leakage and zero uptime loss.

Implement a reliability monitoring and management system to handle plant reliability.

PACKAGE 3 RISK-BASED INSPECTION (RBI) - QUANTITATIVE APPROACH

Risk-Based Inspection (RBI) program focuses on both the likelihood and consequence of failure to prevent plant explosion, Moreover, it can prevent unpredicted leakage and reduce financial loss from plant downtime. Also, Preventative Maintenance (PM) task optimization can enable 50% savings from inspection costs.

REPCO NEX successfully implements RBI for many clients to increase cost-saving and less inspection with better performance.

Thai regulation requires internal inspection to prevent undesirable consequences. In order to prolong intervals with similar safety aspects, REPCO - RIsk - Based Inspection (RBI) is your choice.

"Put the right resource on critical equipment with our best practice."

PACKAGE 4 CORROSION UNDER SUPPORT (CUS) SOLUTION

CUS solution comprises 3 major tasks to ensure that CUS problems will be diminished.

- Priority Assessment: By using data-driven and visual inspection results.

- Access to the CUS Area: REPCO NEX lift-up device enables accessibility to the CUS area with minimum risk of pipe failure during lifting (stress monitoring, stress reduction tool).

- Repair: The pipeline condition by coating, wrapping, or replacement to ensure safe and long-term operation.

Our CUS Solution

- Best-in-class and one-stop CUS management solution.

- Innovative pipe lift-up device.

- 100 times cheaper than conventional method such as cutting & dropping pipe support beam.

- Effective inspection and maintenanc from directly measure and/or repair the corroded areas.

PACKAGE 5 CORROSION UNDER INSULATION (CUI) MANAGEMENT

Corrosion under Insulation (CUI) is one of the most critical plant problems. The possibility of leakage due to CUI problems increases over time especially when the plant age is over 10 years. An effective management system is essential for preventing unexpected hydrocarbon or chemical leakage.

Our Success Cases

- 5 times better detectability of potential CUI leakage by our practices.

- Zero hydrocarbon leak from CUI

Our Approach

- Strategy development: a road map and long-term budget plan.

- Inspection plan: right point and right method.

- Inspection execution

- Continuous improvement

- Monitoring system by CUI sensor - reduce inspection and maintenance cost

- REPCO NEX thermal spray aluminum: prolong lifetime x3

PACKAGE 6 FLANGED JOINT CARE

There are more than 1 million joints in each petrochemical plant and most of the flanged points leakage is caused by the aging of gaskets and sealing materials, inappropriate material selection, and insufficient workmanship. etc. Leakage is more concerned when the pipeline or equipment contains hazardous chemicals such as hydrocarbon, high-pressure steam, etc. Our solution will provide a sustainable management program to prevent leakage of containment (LOC) from any flanged joints.

PACKAGE 7 NON-METALLIC MANAGEMENT

Provide customers the best managing process for aging non-metallic materials such as plastic (PE, PP) rubber (FRP - Fibre Reinforced Plastic) containing hazardous substances, and chemical products which need sufficient maintenance and reconditioning program to prevent leakage and prolong product usage lifetime.

REPCO NEX develops a package to help our customers set up an effective maintenance and inspection program to maximize equipment in our experience including wastewater treatment, acidic related processes, chemical treatment units,s, etc.